AI for industrial manufacturing: intrinsic component identification and traceability

Identifying and tracing a component with its individual characteristics at any time during processing is a prerequisite for many process-influencing decisions in production. However, various object markings are only suitable to a limited extent because they do not remain permanently and/or undamaged on the object: if the surface changes during processing, identification is no longer possible.

In this project, therefore, non-destructive testing (NDT) methods are used to identify the component based on features from inside the component - such as material properties or tolerable "defects". By combining several sensory methods, this approach to component identification is optimal for different metallic materials (e.g., steel, aluminum) and different component types (sheet metal, castings, etc.).

Optimal part identification by Deep Learning network

The material properties are recorded by an inductive sensor array, which is used to detect a component area of approx. 50 x 60 mm² within 0.5 seconds. The sensor-derived identification data (features) are stored in a data space and enable the unique recognition of the component.

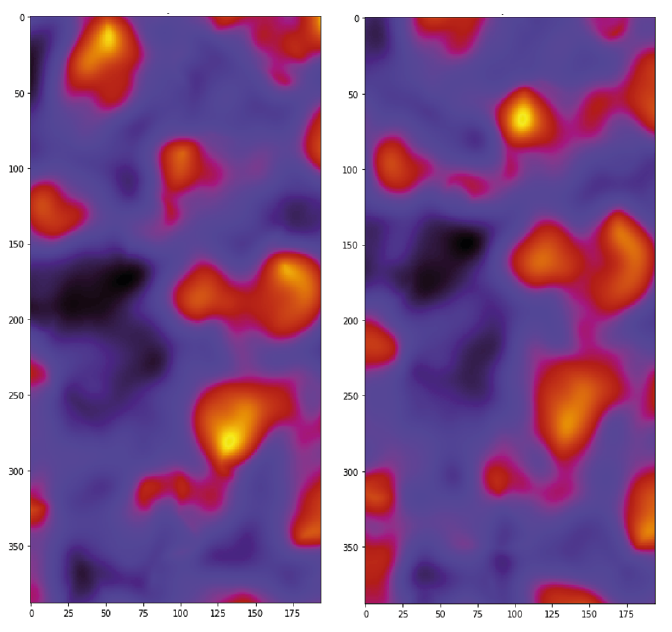

For identification, a Deep Learning approach in the form of a Siamese Convolutional Neural Network is implemented. This requires extensive representative data collection (Big Data) but offers the highest precision in the long run. Two networks are used for this purpose. One network generates a kind of identification key, while another network determines whether it has been captured before, i.e., had a match. In addition, it is possible to work directly with the raw data because the network both extracts the features independently and compares them with the stored data. To this end, Fraunhofer IZFP supplemented existing sensor systems with the additional functionality of component identification, for example for the quality inspection of cast components. The software for unique intrinsic component identification was implemented by Fraunhofer ITWM using a Deep Learning method.

Reliable guarantee of identification and traceability

Especially in the self-organizing, cross-company value creation networks of the future (Industry 4.0), this traceability will be indispensable. Conventional object markings, such as labels, barcodes, etc., cannot usually remain permanently and undamaged on the object to be identified for production reasons. However, the developed Deep Learning method uses stable features to enable identification and traceability even if only a part can be captured. This is of particular importance for the increasingly individualized production of the future, as enabled by Industry 4.0.

Research Center Machine Learning

Research Center Machine Learning